V-ROD Fiberglass Rebar

Manufactured by Pultrall

Our strength lies in the expertise of our team, our innovative mindset, and our commitment to developing high-performance, value-added solutions. Whether you’re looking for custom pultrusion profiles or exploring advanced alternatives to traditional materials like steel, wood, or plastic, Pultrall is the partner you can trust—strong, flexible, and forward-thinking.

As the manufacturer of V‑ROD composite reinforcing bars, Pultrall combines deep technical know-how with a rigorous, ISO 9001 and ISO 14001 certified production process. V‑ROD has been manufactured since 1987 using high-strength glass fibers and corrosion-resistant vinyl ester resin, delivering excellent tensile performance and long-term durability in aggressive environments.

Contact Us to Learn More or Get a Quote

Documentation

FAQs

STRUCTURAL: Can you cut and splice GFRP the same as steel?

For cutting, use a diamond blade cut-off or chop saw. A grinder or hacksaw could also be used in the field if a cut-off saw is not available. Shearing of GFRP bars, as used by steel fabricators, must be avoided as it will split or damage the fibers. Splicing GFRP is permitted and can be estimated using the design codes. Similar to steel rebars, a rough rule of thumb of 60x the bar diameter might be applicable.

STRUCTURAL: Can you use GFRP in areas where fire may be a concern?

Full-scale slab fire tests with VROD reinforcement were conducted at the National Research Council in accordance with ASTM E119. The slabs underwent a 3-hour fire rating, with a minimum cover of 40 mm and a 200 mm unexposed anchor zone at the ends. Additionally, GFRP is included in the CSA S413 parking garage code. The CSA S806 provides guidance on how to detail GFRP bars to achieve the desired fire rating

STRUCTURAL: What is the required concrete cover for GFRP-reinforced elements?

GFRP bars have a superior corrosion resistance; thus, concrete cover can generally be reduced when using GFRP bars. Codes and standards determine the minimum concrete cover.

Have a specific question? Reach out, we love talking solutions!

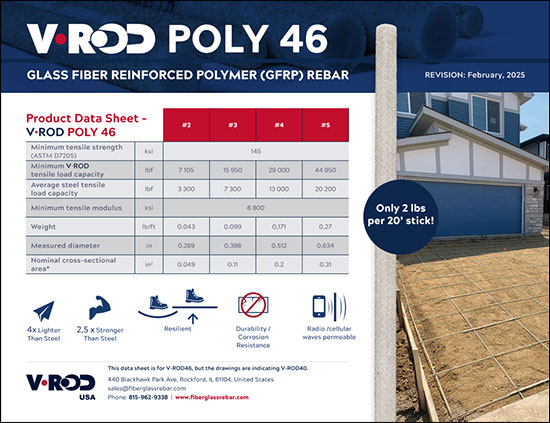

NON-STRUCTURAL: What are the suitable applications for VROD Poly?

The V‑ROD Poly products (Poly 46) are recommended for non-structural applications, as defined by the codes and standards. For instance, V‑ROD Poly in slab-on-grade reinforced for concrete shrinkage and temperature change provides a cost-effective alternative. The engineering department at V‑ROD can assist in identifying the feasibility of using one of the V‑ROD Poly lines based on the element geometry and applied loads.

NON-STRUCTURAL: What is the difference between VROD Poly and VROD Vinyl?

Both materials have similar mechanical properties and are specified by the Canadian Specifications CSA S807. While both materials are highly durable and non-corrosive, the durability of V‑ROD Vinyl was determined to be superior to V‑ROD Poly.

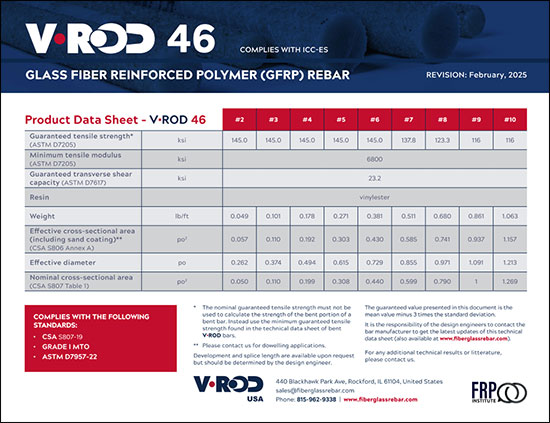

V-ROD 46

V-ROD 46